Cutting-edge X-ray inspection method for 100% defect detection

X-ray inspection systems are used wherever defects need to be detected by non-destructive means. The spectrum of use is broad and ranges from quality controls for complex assemblies, to the testing of materials for cracks and air inclusions, to foreign matter inclusions and shape deviations. The trend toward miniaturization, higher packing densities, and the relocation of components to the interior of the assembly require precise X-ray inspections that detect hidden defects quickly and reliably. X-ray systems from Viscom are used for the inspection of series assemblies as well as sampling and prototype controls. They take care of typical inspection tasks in concealed areas such as void controls, THT filling level measurements, and HIP inspections. At the same time, the systems reliably determine defect features such as coplanarity and polarity – at high inspection speeds and in a cost-effective way.

Flexible and universal: manual X-ray inspection (MXI)

When AOI systems reach their limits, electronics manufacturers turn to flexible universal X-ray systems. These systems can be used to inspect die bonds, BGAs, flip chips, and voids in surface soldering.

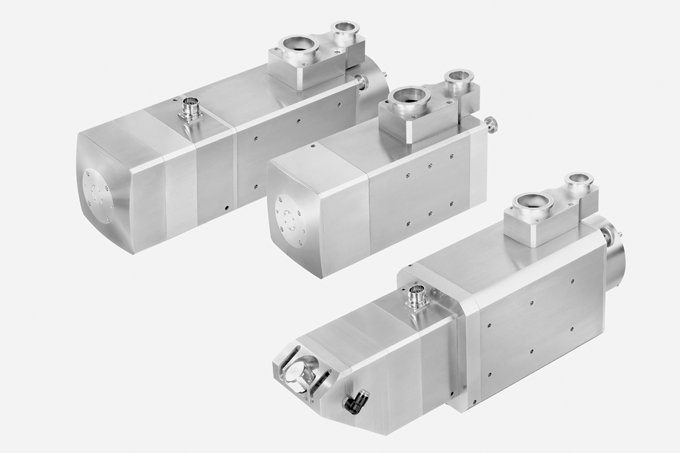

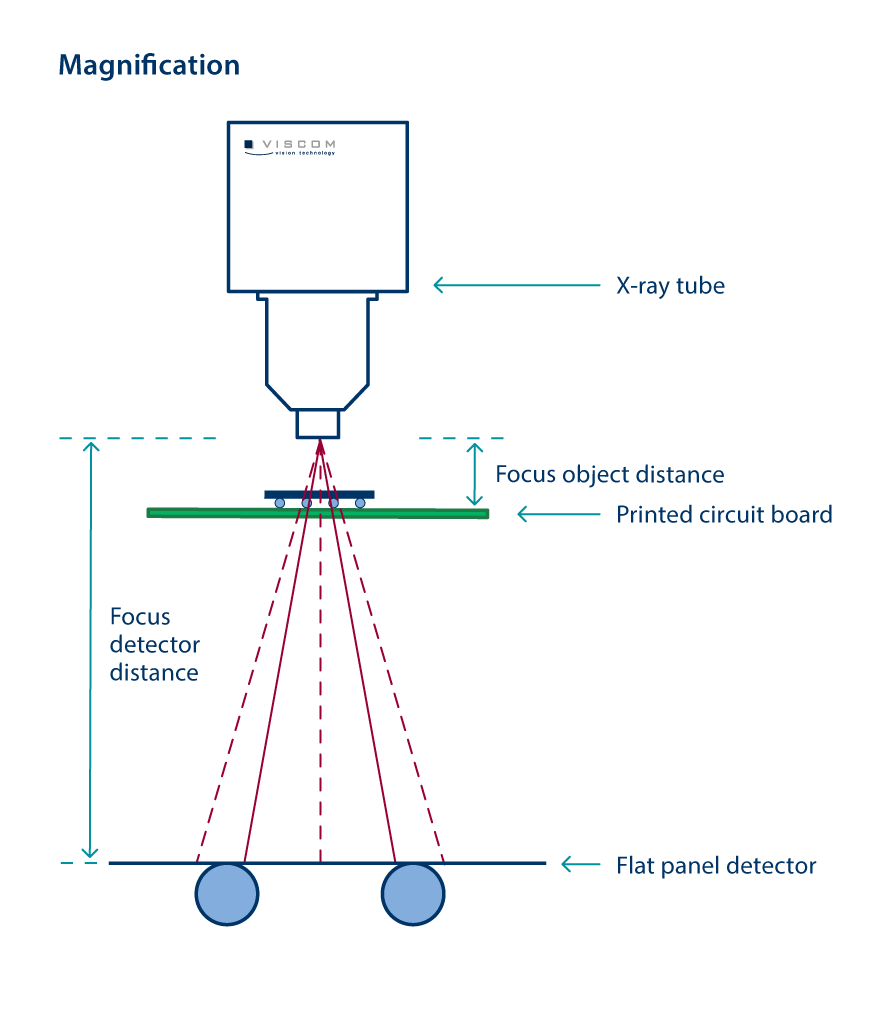

3D reconstruction is also possible with Viscom’s proprietary XVR computer tomography (CT). This means defects can be detected, volumes reconstructed, and structures measured in real units of measurement, and individual layered or sectional images can be created. Excellent image results can be achieved using microfocus transmission tubes that are developed and manufactured in-house. The technology meets all the requirements in terms of resolution, stability, and lifetime. High-resolution digital flat panel detectors are used for the highest magnifications and optimum image quality for the evaluation of X-ray images. In addition to an object stage, Viscom offers a 360° rotation module and a motorized rotation and tilt axis.

Meets the highest cycle time requirements and inspection quality: 3D inline automatic X-ray inspection (AXI)

While the technology underlying inline automatic X-ray (AXI) and automatic optical inspection (AOI) differs, both systems are ultimately designed to provide fast assembly handling and first-class 3D image quality. Today, inline X-ray inspection can achieve handling times of up to four seconds, enabling 3D AXI systems to handle up to three circuit boards at the same time. Faster 2D and 2.5D inspections can be combined with 3D inspections as needed.

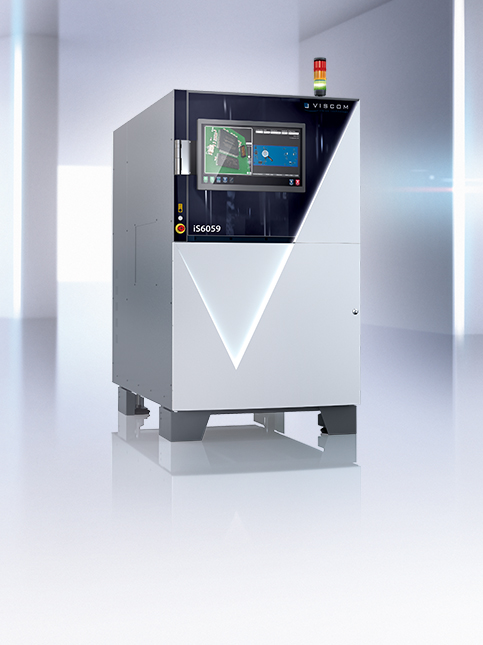

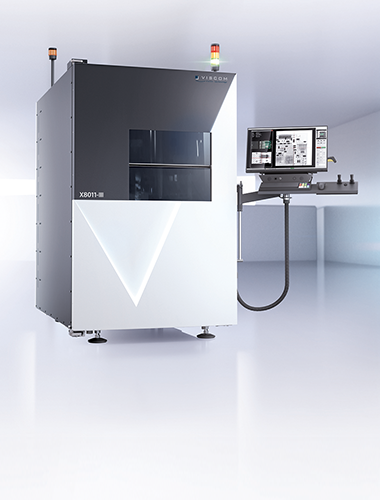

The X7056-II has proven itself among electronics manufacturers as the ideal solution for inspecting assemblies, offering high-speed handling and covering all inspection requirements perfectly thanks to a combination of 3D AOI and AXI in a single system. The innovative iX7059Heavy Duty Inspection is used for 3D inline X-rays under the most demanding conditions involving large, heavy, and solid circuit boards, power electronics, and energy storage with integrated CT. When it comes to manual inspection tasks, the X8011-III for universal use and the X8068. for large inspection objects impress as offline or stand-alone solutions in production or for laboratory applications.

ADVANTAGES

- Cutting-edge 3D X-ray technology

- 3D reconstruction via CT

- Precise and comprehensive documentation of test results

- User-friendly, flexible systems

- Ideal for various inspection tasks