iS6052 SPI – reliable 3D solder and sinter paste inspection

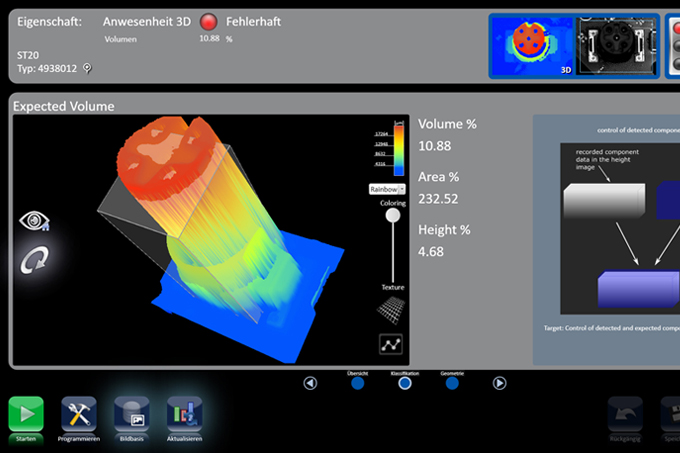

Introducing the iS6052 SPI, Viscom's solution for inspecting solder paste applications in SMD production with remarkable efficiency and accuracy. Emerging from over forty years of expertise, this 3D inline system meticulously evaluates critical features like volume, height, and shape, alongside surface area, displacement, and smearing. Equipped with innovative sensor technology including an orthogonal camera and four lateral views, it ensures unparalleled inspection quality. Realistic color imaging facilitates swift and precise verification, while the Fast Flow handling system guarantees exceptional throughput by synchronizing assembly input and output. With minimal handling times and reduced mechanical impact, this system optimizes efficiency without compromising performance. Intelligent networking capabilities further bolster process stability and streamline operations within the SMT line.

- Robust system design

- Ideal system configuration with respect to costs/benefits

- High inspection speed

- One orthogonal camera and eight angled-view cameras provide virtually shadow-free 3D inspections

- Verified zero defect slippage thanks to integrated verification

- Flexible integration into existing productions

- Improved ergonomic design

- Global libraries, global calibration: transferability to all systems

- Intelligent software add-ons such as integrated verification or Viscom Quality Uplink for effective networking

- Traceability, offline programming, statistical process control

- Communication with MES systems

- Independent real-time image processing with Viscom analysis tools

- High-performance OCR software

- optional connection to the digital multi-purpose platform vConnect

| Inspects solder paste deposits (pad sizes of 01005 components) and dispenser paste for surface, height and shape |

| Defects/defect features: too much/too little solder, missing solder, print displacement (X/Y offset), paste smearing |

| Optional: coplanarity, open area analysis, OCR, DMC |

| DIMENSIONS | |

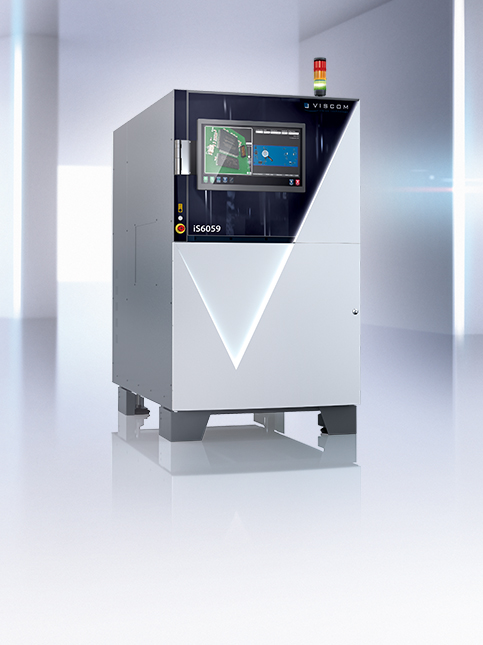

| System housing: | 997 mm x 1756 mm x 2047 mm |

| (39.3" x 69.1" x 80.6") (W x D x H) | |

| CAMERA TECHNOLOGY | XM SPI |

| 3D sensor technology | |

| Z-resolution: | 0.1 µm |

| Z-range: | Up to 5 mm |

| (0.2") | |

| Angled view cameras | |

| Number of megapixel cameras: | 4 |

| Orthogonal camera | |

| Resolution: | 12 µm |

| Field of view: | 58 mm x 58 mm |

| (2.2" x 2.2") | |

| INSPECTION SPEED | Up to 80 cm²/s |

| HANDLING | |

| PCB dimensions: | 508 mm x 508 mm (20" x 20") |

| SOFTWARE | |

| User interface: | Viscom vVision |

| Statistical process control: | Viscom vSPC/SPC, open interface (optional) |

| Verification station: | Viscom vVerify |

| Remote diagnosis: | Viscom SRC (optional) |

| Programming station: | Viscom PST34 (optional) |

Advantages at a glance

- Proven 3D camera technology

- Designed specifically for most applications in production

- Meets demanding cycle time requirements

- Closed loop functions with solder paste printer and pick-and-place machine

- Effective process control and optimization in real time