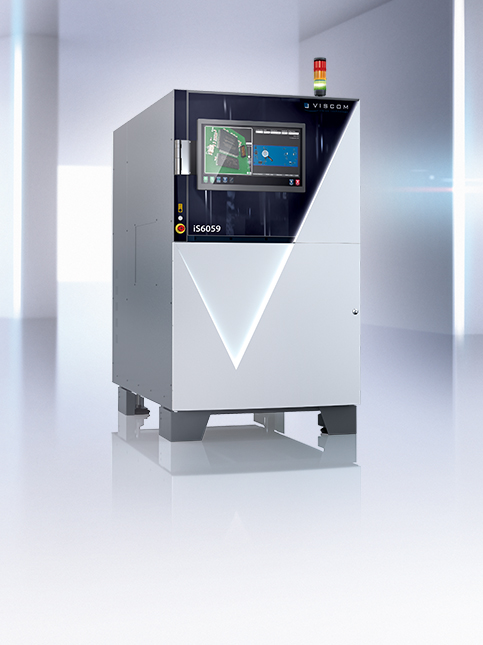

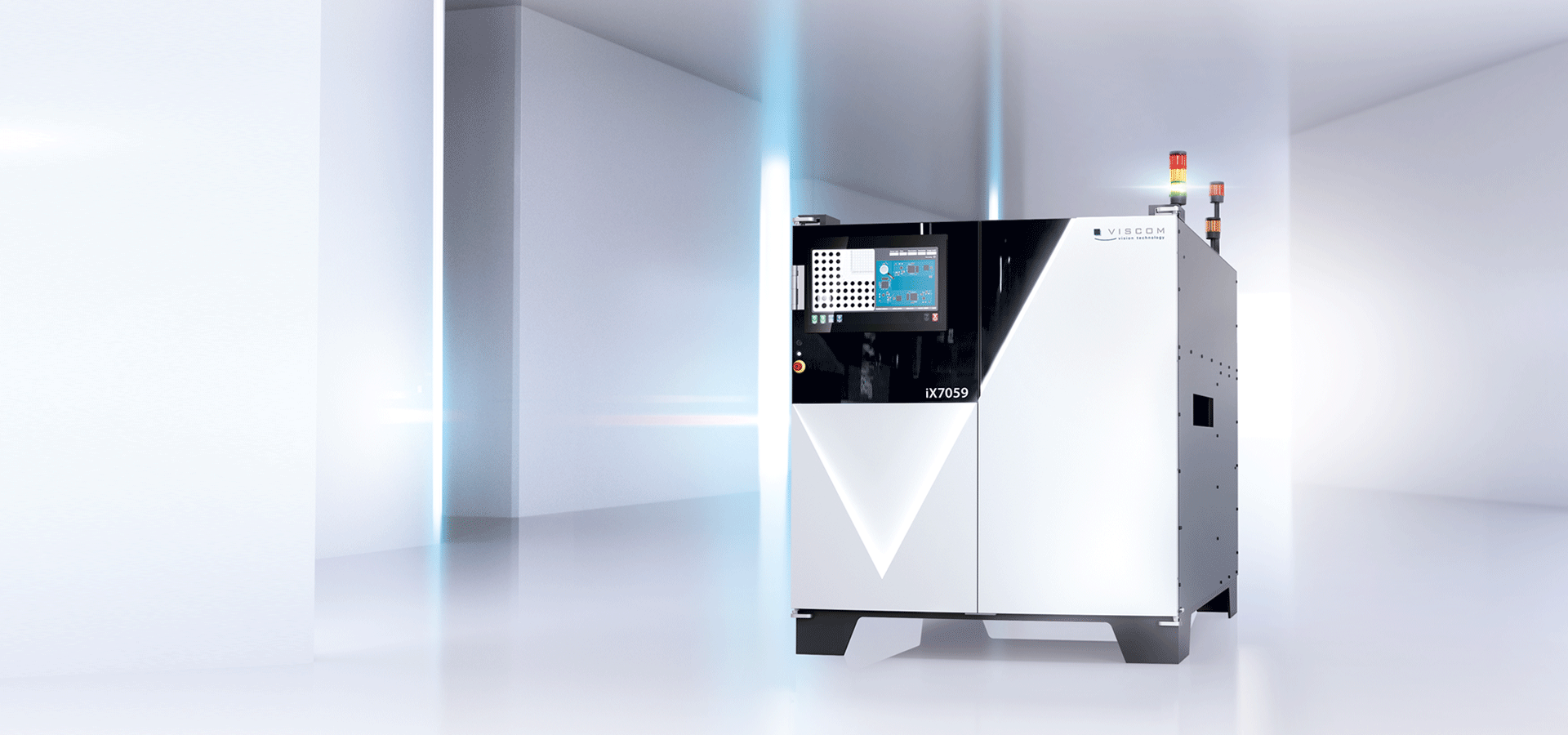

iX7059 One – The ONE ideal inspection system for your advanced assembly, power module and semiconductor production.

In the pursuit of excellence, precision is non-negotiable. With the iX7059 One, precision is not just a goal; it is a guarantee. Equipped with state-of-the-art imaging capabilities, this system delivers unrivaled image quality down to an astonishing 1μm resolution. From intricate semiconductor devices to complex leadframe applications, every detail is captured with breathtaking clarity.

But precision extends beyond mere image quality. Its about the ability to identify and address defects with unwavering accuracy. Here, the iX7059 One shines brightest, boasting a greater depth of field that sets a new benchmark in defect detection. Whether it is a subtle flaw or a glaring imperfection, rest assured that nothing escapes the meticulous gaze of this advanced inspection system.

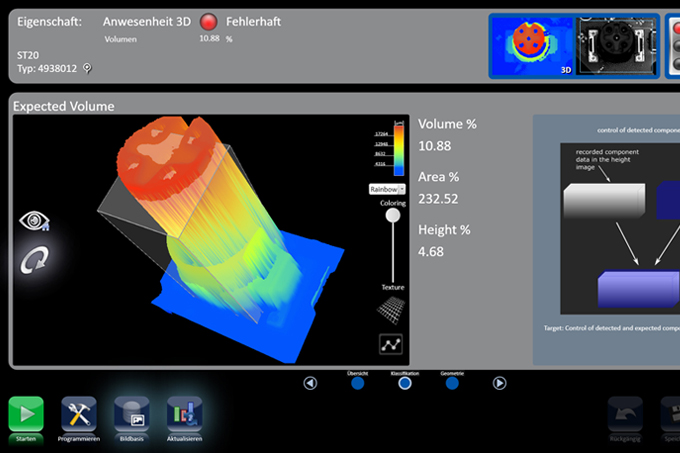

What sets the iX7059 One apart is its versatility. With X-ray Inspection capabilities spanning 2D, 2.5D, and 3D, it is equipped to handle the diverse needs of modern manufacturing. From single semiconductor devices with intricate internal structures to leadframe applications requiring comprehensive analysis, this system delivers flexibility from standalone to unparalleled 100 % inline inspection for production performance across the board.

- Resolution down to 1 μm for extremely accurate measurements

- Set a new benchmark in quality assurance with an extended depth of field

- Ultra precise X-ray inspection in real 2D, 2.5D and 3D

- From RnD to inline inspection („Lab-to-Fab“)

- Tailored for semiconductor devices, leadframe applications, and advanced assembly products.

- Modern operating software for extremely fast programming and incredibly simple verification

- Maximum inspection program optimization through integrated verification

- Service, hotline support and remote maintenance worldwide

- Global libraries, global calibration: transferability to all systems

- Automated grayscale value calibration for consistent inspection results

- Traceability, statistical process control, offline programming, multiline verification

- Viscom Quality Uplink: effective networking and process optimization

- Interfaces: SMEMA, SECS/GEM, IPC Hermes Standard (optional)

| Solder bump inspection, microcracks, void analyses, leadframe inspection, solder layer quality, cold solder joints, solder joint morphology, HiP for solder bumps, wirebond defects, advanced packaging applications |

| DIMENSIONS | ||

| System housing: | 997 mm x 1756 mm x 2047 mm (W x D x H) | |

| (39.3" x 69.1" x 80.6") (W x H x D) | ||

| X-RAY TECHNOLOGY | ||

| X-ray tube: | Sealed microfocus X-ray tube | |

| High voltage: | 110 kV (up to 130 kV optional) | |

| Detector: |

Flat panel detectors type FPD T2 (T3 optional) | |

| Resolution: | 1 – 25 µm/pixel | |

| HANDLING | ||

| iX7059 One - Leadframe | iX7059 One - Carrier | |

| Inspection Product dimensions: | Up to 500 mm x 550 mm (19.7" x 21.6") (L x W)* | Up to 500 mm x 500 mm (19.7" x 19.7") (L x W)* |

| Inspection Product weight: | Up to 15 kg (33 lbs) | Up to 15 kg (33 lbs) |

| SOFTWARE | ||

| User interface: | Viscom vVision | |

| *Depending on configuration |

ADVANTAGES AT A GLANCE

- Resolution down to 1 μm

- Detects voids/cracks early in manufacturing process

- Robust system design

- Can be used for both standalone and 100% inline applications

- Leadframe and carrier variants

- Works seemlessly with standard interfaces

- Long-term investment security